Every tonne counts. Every cycle matters. In mining, efficiency isn’t just a buzzword, it can be the difference between profit and loss. The way we manage payloads directly impacts productivity, fuel costs, and equipment longevity.

Hitting the Payload Sweet Spot: Maximising Efficiency, Minimising Costs

In mining operations, payload optimisation is key to reducing cost per tonne. Highest amount of load per cycle without compromising the truck integrity.

The manufactures provide a tolerance for maximum load accounting for road conditions humps and bumps that generate significant stress to the chassis due the inherent inertia carrying. As such, they do tolerate higher payload (if material density allows), however, too much is detrimental in the long run.

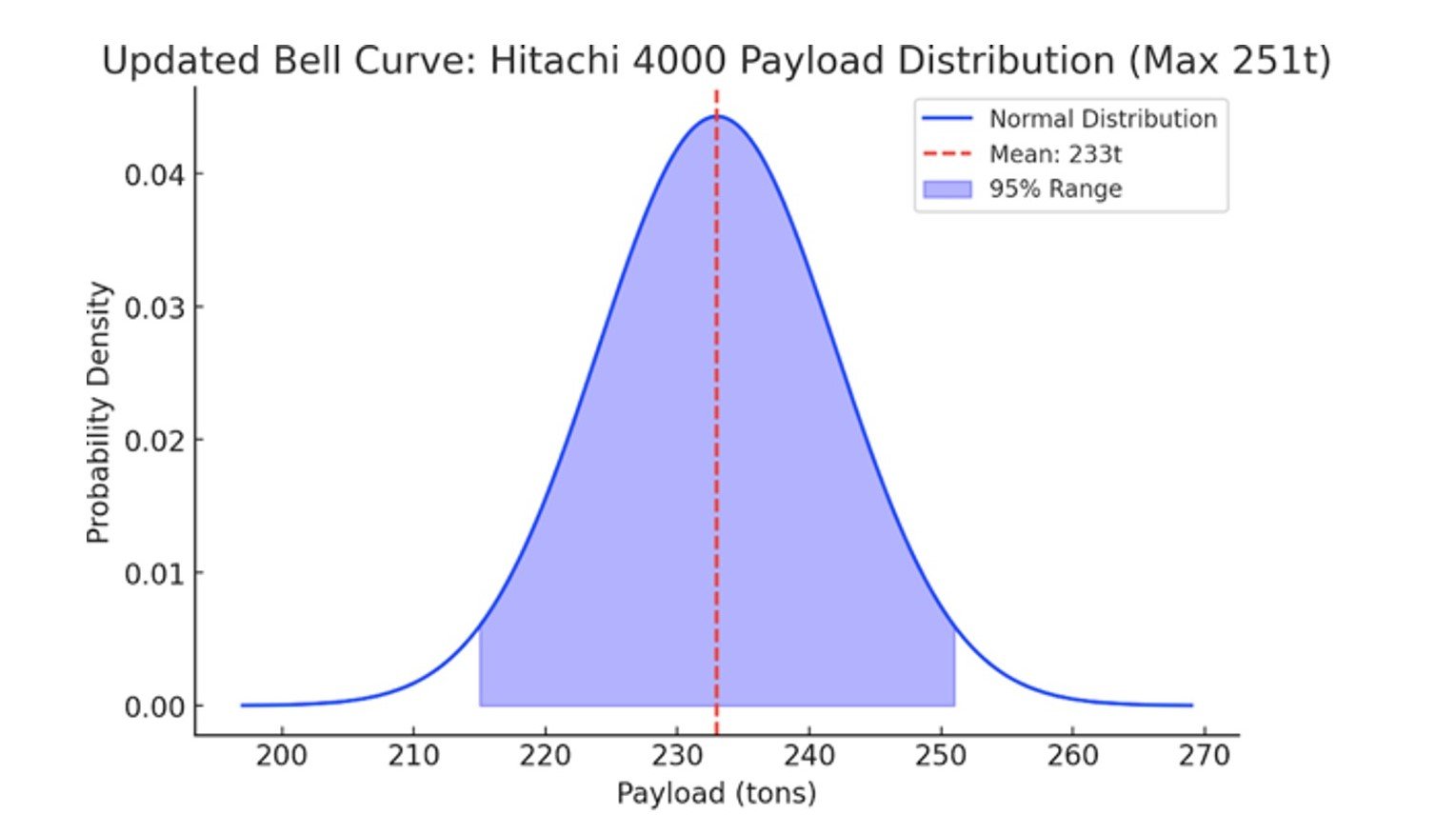

This means that the narrower the load distribution the higher the payload can be.

So, what is the optimal operational target to maximise the payload?

Best practices suggest 95% of loads within the optimal range – delivering maximum productivity without compromising equipment integrity. Here’s why it matters:

• Underloading: Wastes fuel, reduces tonnes moved, and increases cost per tonne.

• Overloading: Drives up fuel consumption, accelerates equipment wear, and leads to higher maintenance costs.

• Optimised Loading: 95% in range moves more tonnes per cycle at the lowest cost, maximising efficiency while protecting equipment.

The $/Tonne formula – why it matters

Everything comes down to cost per tonne. The more material we move for the same cost, the more efficient and profitable we become. Every decision, from loading to haulage and dumping, affects this bottom line. Increase payloads by 5% or narrow the loading spread improves the mining unit cost between 2% and 3%.

How do we make this happen? – Operator behaviour – the biggest factor

• The operator is the biggest difference maker – know the target seek conformance

• Smooth loading, proper bucket fills, and controlled acceleration all increase efficiency.

• Small habits = big results.

Machine matching – the right tool for the job

• Pairing the right excavator with the right truck reduces cycle times and increases efficiency.

• Too small? You’re wasting valuable loading time.

• Too big? You’re burning unnecessary fuel.

Drill & blast – setting up for success

• Poor fragmentation, difficult to achieve target payload.

• Optimised fragmentation means faster, smoother, and more efficient loading.

• Better fragmentation reduces unnecessary cycle delays and supports higher payload consistency.

Road Conditions – the quality of road maintenance

• Roads with continuous smooth lines, reduces the load inertia per cycle, enabling higher payload.

Team targets & accountability

• What gets measured, gets improved.

• Setting clear team targets drives better results.

• When operators know their numbers, they work smarter.

Final thoughts

Optimising payloads is not just about moving more material it’s about doing it smarter, safer, and more efficiently. Every operator, leader, and planner plays a role in getting it right. By leveraging technology, strategic models and good old-fashioned teamwork, we can turn payload optimisation into a competitive advantage.

So, are you ready to make every tonne count?

Would you like to know more?

Shaping Earth, Crafting Futures, The Essence of Our Mining Identity. Get A Free Estimate!