Before we discuss how maintenance strategies can save you money, first explain what maintenance strategies entail. To keep it simple, maintenance strategies are the program of maintenance activities that must be performed to the assets so they can deliver the required productive outcome. A big component of maintenance strategies is the Preventative Maintenance Program, but these can also include other activities such as overhauls, major component change outs, condition monitoring tasks, etc. It is important to note that all these activities cost time and resources and can have a significant impact to the financial performance of the organisation.

Most organisations implement Original Equipment Manufacturer (OEM) recommended maintenance strategies when buying equipment. While they offer a safe start to ensure assets can perform reliably for some time, especially when new, these can be far from optimal. We argue that organisations must seek to optimise these strategies to suit their organisational context which in most cases result in cost savings.

To illustrate our argument, for a mining truck such as Caterpillar 793D the recommended engine change out by the OEM is usually 20,000 hours. The cost of the replacement is approximately A$0.5M. This frequency is an average based on fuel consumption, asset utilisation. engine load, environmental conditions to name a few. If the design of the mine is such as trucks after loaded are hauling downhill instead of uphill, the wear of the engine may be significantly lower.

With oil analysis the engine change-out frequency can be extended from 20k hours up to even 25k hours without compromising the reliability of the engine. On a fleet with 10 trucks, this translates into approximately one less engine change out a year (~A$0.5M per annum savings and less time in workshop = higher mechanical availability). Similar practices can be applied to fleet, including based on hydraulic oil analysis.

Then, how can organisation optimise maintenance strategies? There are various approaches and one of the most known and proven as effective is Reliability Centred Maintenance (RCM). Other approach may be very targeted to achieve specific cost savings as the ones explained above that focused on optimising certain high-cost activities. Other may be more reliability focused targeting eliminating specific equipment issues.

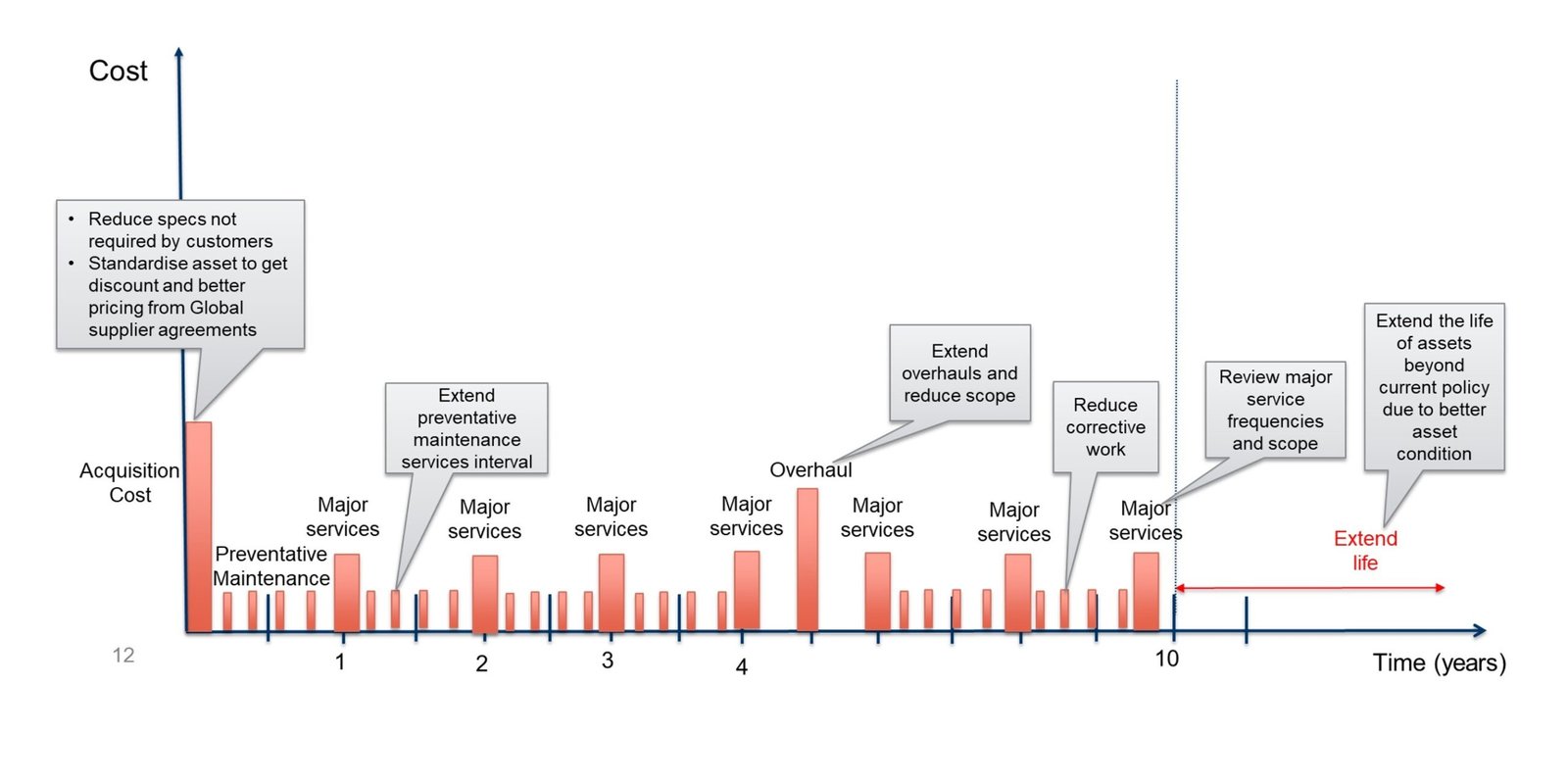

The figure below illustrates options available to optimise asset strategies that deliver significant savings to any organisation. If your organisation is seeking to improve financial and operational performance, we can help you achieve it by optimising your maintenance strategies. We can develop the right approach depending on your organisation priorities so you can achieve the objectives required.

Shaping Earth, Crafting Futures, The Essence of Our Mining Identity. Get A Free Estimate!